We provide tailored solutions for self-supporting towers, monopole towers, and guyed wire towers engineered for telecom and transmission applications.

We support our customers throughout the project to ensure their investment in steel structures for telecom and power networks is truly worthwhile

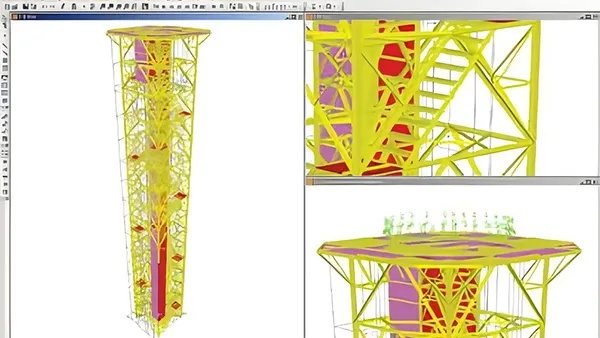

Jiayao provides customized GSM tower design solutions developed in accordance with international standards such as TIA/EIA-222. For projects requiring compliance with TIA/EIA-222-G, our design engineers select the appropriate tower series from the in-house design database and make project-specific adjustments using ASMTOWER software. If no suitable design is available for modification, a new tower structure is engineered from the ground up based on the client’s requirements.

Computer-Aided Structural Analysis

We use the ASMTOWER structural analysis program for tower design. The telecommunication and power steel tower is modeled as a three-dimensional space-frame system, and the software performs the following calculations:

- Determines structural loads based on ANSI/TIA-222-G

- Runs the full structural analysis and calculates internal forces for all tower members

- Evaluates member capacity, stress ratios, and slenderness ratios

- Calculates connection bolt requirements according to design inputs

- Assesses sway and torsional behavior

- Computes foundation reactions for final foundation design

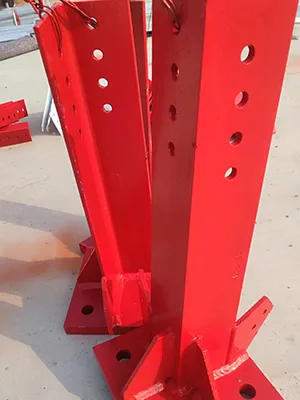

This service mainly covers color customization and coating process selection, based on the environment where the tower will be installed and the functional requirements of each project.

Color Customization

- Environment-based color design

Coating colors are selected according to the surrounding environment. Towers installed in industrial parks usually adopt corporate VI colors such as blue or grey tones. Urban areas usually use soft colors such as beige or light grey to keep a clean look, while creative parks prefer more artistic or painted designs. - Function-oriented coating selection

For high-temperature areas, heat-insulating coatings are used. For coastal areas, salt-resistant fluorocarbon coatings are used to protect the towers from corrosion caused by sea air and humidity.

Coating Process

- Surface preparation

Before painting, metal surfaces are carefully cleaned by sandblasting to remove rust and dirt and reach the Sa2.5 standard. Concrete surfaces are washed with high-pressure water and then treated with a primer to prepare them for coating. - Multi-layer coating system

Any uneven areas are first smoothed with filler. After that, an anti-rust primer and an intermediate coat are applied layer by layer. A fluorocarbon or polyurethane topcoat is applied at the end to protect the surface and give it a clean final look.

Most telecommunication and transmission towers are supplied with hot-dip galvanizing and a protective coating. The height and color can be customized, and maintenance support is also available after delivery.

Installation Support

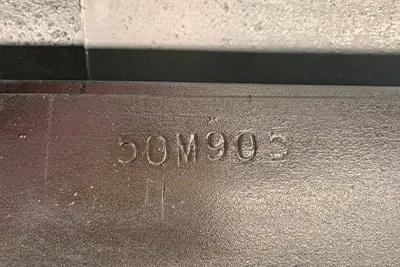

We provide clear and detailed structural drawings for installation. Each part number shown on the drawings matches the stamped number on the actual components, so the structure can be assembled easily by following the drawings step by step.