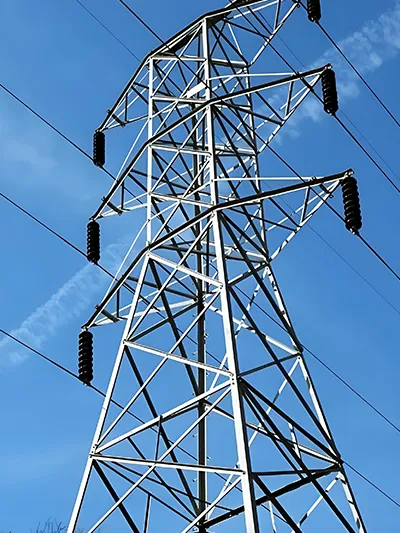

Steel transmission towers are the main structures used to carry overhead power lines. They are commonly found near power plants, substations, and open-field transmission corridors. Most towers range from 25 to 60 meters in height. Their purpose is simple but essential: they hold the conductors at a safe height, protect the lines, and keep electricity moving reliably across long distances.

A transmission tower is made up of several core components. The tower body forms the structural frame and is usually fabricated from angle steel, tubular steel, or welded steel plate. This gives the tower the strength and toughness needed for long-term outdoor service. Cross-arms are installed to support the conductors and maintain even line tension. Insulators sit between the tower and the conductors, preventing leakage and ensuring a safe electrical distance. Connectors and clamps secure the lines and keep them stable during operation. Transmission towers are categorized by structural form. Angular steel towers use bolted angle sections and offer a straightforward design with lower fabrication cost, making them suitable for medium- and low-voltage lines. Tubular steel towers have a cleaner appearance and are often chosen for higher-voltage corridors or projects requiring easier maintenance. Monopole power transmission towers use a single-pole structure with a small footprint, making them a good choice for built-up areas or locations where land availability is limited.

These different tower types give project owners the flexibility to select the right structure based on voltage class, terrain, span length, and aesthetic requirements.

-

- Angular Steel Power Transmission Tower

- Ultimate Tensile Strength: 490kpa-620kpa

- Tolerance of dimension: ±2%

- Manufacturing Standard: GB/T 2694-2018

- Quality Certification: ISO 9001: 2015; COC; Third Party Inspection Report (SGS, BV)

- Nuts & Bolts: Grade 8.8/6.8/4.8; A325, DIN7990, DIN931, DIN933; ISO4032, ISO4034

- Main Material: Q235B/Q355B/Q420B Angle Steel

- Height Range: 5–60 m, customizable according to project requirements

- Design Wind Speed: Up to 300 km/h, adjusted according to site conditions

- Surface Treatment: Hot-dip galvanized

-

- Tubular Steel Power Transmission Tower

- Ultimate Tensile Strength: 490 kPa – 620 kPa

- Min. Yield Strength: 355 kPa

- Manufacturing Standard: DL/T 646-2012, DL/T 5214-2014, DL/T 5220-2021

- Quality Certification: ISO 9001: 2015; COC; Third Party Inspection Report (SGS, BV)

- Nuts & Bolts: Grade 8.8 / 6.8 / 4.8; A325; DIN 7990, DIN 931, DIN 933; ISO 4032, ISO 4034

- Main Material: Q355B tube steel

- Height Range: 5–60 m, as per customer’s requirement

- Design Wind Speed: 0–300 km/h, adjusted according to regional conditions

- Surface Treatment: Hot-dip galvanized

-

- Monopole Power Transmission Tower

- Type: Single Circuit Tower, Double Circuit Tower, Multi Circuit Tower

- Manufacturing Standard: DL/T 646-2012, DL/T 5214-2014, DL/T 5220-2021

- Quality Certification: ISO 9001: 2015; COC; Third Party Inspection Report (SGS, BV)

- Nuts & Bolts: Grade 8.8 / 6.8 / 4.8; A325; DIN 7990, DIN 931, DIN 933; ISO 4032, ISO 4034

- Main Material: Q355B Plate steel

- Height Range: 5–60 m, as per customer’s requirement

- Design Wind Speed: 0–300 km/h, as per customer’s requirement (varies by region)

- Surface Treatment: Hot-dip galvanized

-

Angular Steel Power Transmission Tower

Angular Steel Power Transmission Tower

-

Angular Steel Power Transmission Tower

Angular Steel Power Transmission Tower -

Tubular Steel Power Transmission Tower

Tubular Steel Power Transmission Tower

-

Tubular Steel Power Transmission Tower

Tubular Steel Power Transmission Tower -

30-meter Power Transmission Tower

30-meter Power Transmission Tower

With family experience dating back to 1984, Jiayao delivers steel tower solutions built with high-grade materials, heavy-duty galvanizing, and designs compliant with ANSI/TIA and Eurocode standards. Our steel structures are engineered for high wind resistance and easy installation, ensuring reliable performance across diverse environments.