We provide tailored solutions for self-supporting towers, monopole towers, and guyed wire towers engineered for telecom and transmission applications.

We manufacture different types of steel telecommunication towers, including angular towers, tubular towers, monopoles, guyed towers, telescopic towers, and camouflaged tree towers. These towers are used in telecom, broadcasting, television, and power projects, where they support the construction and operation of networks for different operators and infrastructure providers. Engineering and technical support are provided throughout the project cycle, from early design to installation. Our engineering team supports clients with structural design concepts, technical consulting, and basic software guidance when needed. Our technical team supports overseas projects by working closely on production, shipment, and on-site installation to keep everything running smoothly.

We source our steel raw materials from renowned Chinese producers such as HBIS Group, Baowu Steel Group, and Shougang Group.

Monopole Telecom Tower Workshop

This CNC production line is used for manufacturing steel towers for telecom and transmission networks

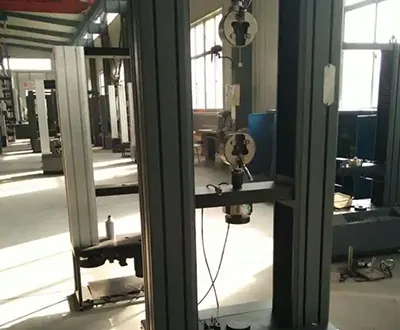

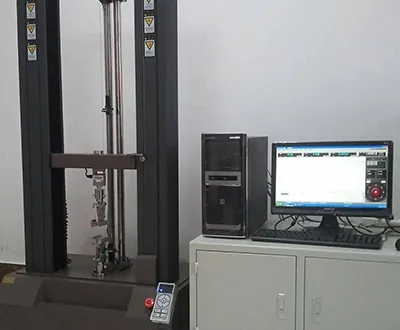

Mechanical Performance Testing

Q235 and Q355 steel materials are tested for mechanical performance to ensure they comply with the requirements of GB/T 700 (carbon structural steel) and GB/T 1591 (low-alloy high-strength structural steel)

Dimensional & Visual Inspection

Dimensions and appearance are carefully checked to match the design requirements. The surface must be smooth and clean, with no air bubbles, cracks, scratches, or burrs, ensuring a neat and consistent finish

Pre-assembly inspection

Pre-assembly inspection Packing of bolts & fasteners

Packing of bolts & fasteners Angle steel connecting parts

Angle steel connecting parts Final parts inspection before packing

Final parts inspection before packing Angle steel connection parts

Angle steel connection parts Connection plates

Connection plates Antenna poles

Antenna poles Container loading for shipment

Container loading for shipment Assembly

Assembly Protective packing for shipment

Protective packing for shipment Stamp for product identification

Stamp for product identification Tower foot components

Tower foot components

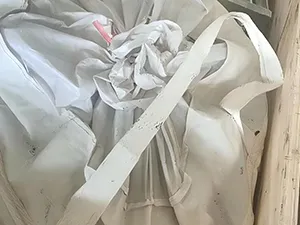

Packaging Operation Standards

- Preparation before packing: Any parts that can be disassembled are removed in advance and packed separately. This helps reduce the risk of damage caused by vibration during transport.

- Fixing and strapping method: Materials are secured using high-strength steel straps with a minimum width of 19 mm, tensile strength of at least 800 MPa, and a tension capacity of 2500 N. Steel plates are strapped in a cross pattern inside the container to keep the load stable and prevent shifting during shipping.

- Packaging of tower materials: Steel pipes, plates, and angle steel parts are first sorted by type, then tied together as complete bundles and carefully loaded into the container to keep everything safe during transport.

Wooden Crate Packing (Customizable on Request)

When the shipment does not fill a full container or the order volume is small, consolidated shipping or partial load delivery can be arranged to help reduce logistics costs. For this type of shipment, wooden crates are used, with each crate able to hold up to 2 tons safely during transport.