Jiayao provides customized GSM tower design solutions developed in accordance with international standards such as TIA/EIA-222. For projects requiring compliance with TIA/EIA-222-G, our design engineers select the appropriate tower series from the in-house design database and make project-specific adjustments using ASMTOWER software. If no suitable design is available for modification, a new tower structure is engineered from the ground up based on the client’s requirements.

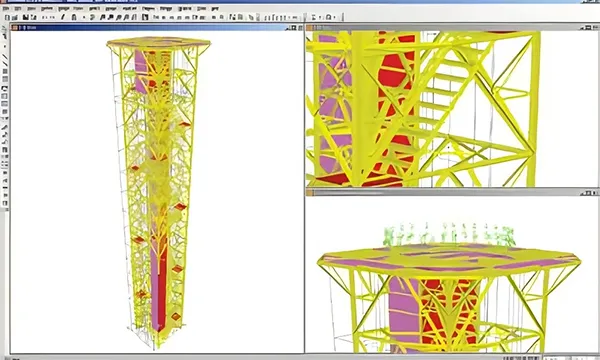

Computer-Aided Structural Analysis

We use the ASMTOWER structural analysis program for tower design. The telecommunication and power steel tower is modeled as a three-dimensional space-frame system, and the software performs the following calculations:

- Determines structural loads based on ANSI/TIA-222-G

- Runs the full structural analysis and calculates internal forces for all tower members

- Evaluates member capacity, stress ratios, and slenderness ratios

- Calculates connection bolt requirements according to design inputs

- Assesses sway and torsional behavior

- Computes foundation reactions for final foundation design

Raw Material Selection Standards

- Q235: Recommended for light and medium-duty towers

- Q355 / Q420: Used for taller towers or long-span structures

- Q355 / Q420: Common grades for tapered welded tubular sections

| Certification Standard | ||

| Design Code | TIA/EIA-222-G/H/F, EN 1991-1-4 & EN 1993-3-1; 3-second gust wind speed; North American (EIA, UBC, CSA) standards; European (Eurocode) | |

| Structure Steel | ||

| Grade | Mild Steel | High Tensile Steel |

| GB/T 700: Q235B, Q235C, Q235D | GB/T1591: Q355B, Q355C, Q355D, Q420B | |

| ASTM A36 | ASTM A572 Gr50 | |

| EN10025: S235JR, S235J0, S235J2 | EN10025: S355JR, S355J0, S355J2 | |

| Design Wind Speed | Up to 300 km/h | |

| Allowable deflection | 0.5–1.0° at operational speed | |

| Tensile strength (Mpa) | 360–510 | 470–630 |

| Yield strength (t ≤ 16 mm) (MPa) | 235 | 355/420 |

| Elongation (%) | 20 | 24 |

| Impact strength KV (J) | 27 (20°C) - Q235B / S235JR | 27 (20°C) - Q355B / S355JR |

| 27 (0°C) - Q235C / S235J0 | 27 (0°C) - Q355C / S355J0 | |

| 27 (−20°C) - Q235D / S235J2 | 27 (−20°C) - Q355D / S355J2 | |

| Bolts & Nuts | ||

| Grade | Grade 4.8, 6.8, 8.8 | |

| Standards for mechanical properties | ||

| 1 Bolts | ISO 898-1 | |

| 2 Nuts | ISO 898-2 | |

| 3 Washers | ISO 6507-1 | |

| Standards for Dimensions | ||

| 1 Bolts | DIN7990, DIN931, DIN933 | |

| 2 Nuts | ISO4032, ISO4034 | |

| 3 Washers | DIN7989, DIN127B, ISO7091 | |

| Welding | ||

| Method | CO₂ shielded arc welding & submerged arc welding (SAW) | |

| Standard | AWS D1.1 | |

| Galvanizing | ||

| Galvanization standard of steel sections | ISO 1461 or ASTM A123 | |

| Galvanization standard of bolts and nuts | ISO 1461 or ASTM A153 | |

Our manufacturing workshop specializes in the production of transmission line towers and telecommunication towers, and is fully certified with all required manufacturing licenses for both transmission and microwave communication towers. With an annual production capacity of 60,000 tons, the workshop is equipped with advanced fabrication and testing equipment that supports a high level of automation and process control. This ensures consistent precision, reliable quality, and strong performance across every project.

Our galvanizing workshop operates on a large production scale in China and uses an automated hot-dip galvanizing line to maintain consistent output. The finished coatings provide strengthened surface protection, reliable corrosion resistance, and a clean, uniform appearance.

Jiayao company is located in Hengshui, Hebei Province, with convenient access to major transportation routes. Tianjin Port, one of China’s key seaports, is only a two-hour drive away, ensuring efficient logistics and timely shipment for global projects.

Kenya: 50-meter three-leg tubular steel tower

Gabon: 105m four-leg angular steel tower

Chile: 60m three-leg angular steel tower